Accelerated Bearing Failure Testing

What is It?

Accelerated bearing failure testing on an industrial pump to track the signal degradation of different sensors.

Equipment Involved

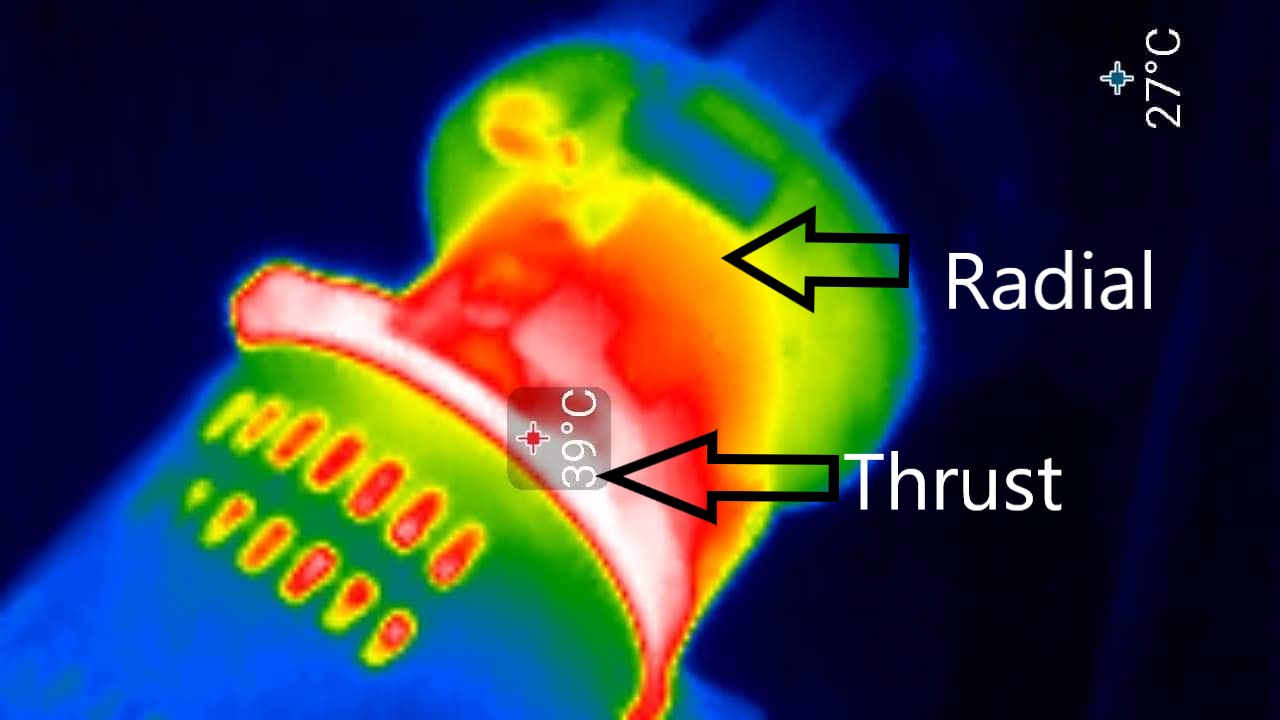

UWA has a Goulds 3196MTX pump in a simple loop system that generates around 10m of head at full flow. The pump is fitted with a 1500W motor, which rotates the shaft at 1432 RPM. The pump has two bearings installed on the driving shaft, a 6309 radial bearing and 5309 thrust bearing. Both of these bearings measure 100mm in diameter (outer).

The pump is located in a workshop, with capacity for drainage and ease in disassembling the pump.The installation of new bearings on the pump can be done exclusively at the UWA campus, requiring a technician or fitter to do the bearing installation.

Methodology

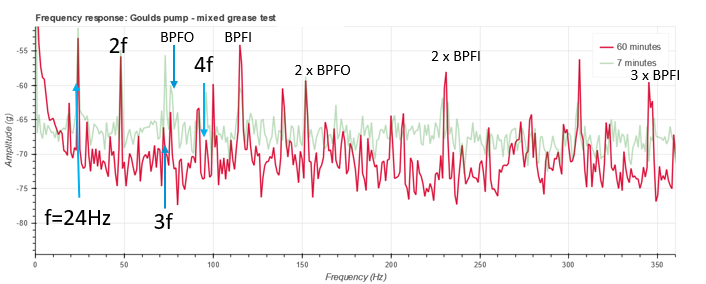

Two different tests have been created for this pump based on the most common failure causes of pumps, failure through lubrication contamination. This was achieved by packing two different greases into the same bearing (Test 1) and mixing dirt sourced from the Pilbara (<70 micrometers) with grease. Both of these tests have proven results of creating failure profiles on the bearing, validated using temperature probes and piezoelectric accelerometers.

There is scope to perform the following tests:- shaft misalignment

- dirt / metal / quarts contamination

- seeded defects in bearing

- mixing greases

Limitations

The bearing changeout process can take some time due to needing an external contractor to strip the pump and replace the bearings.

The pump is located in a shared workspace, and cannot be left unsupervised during testing.

Using a pump for bearing replacements can take more time due to seal breakages and needing to order replacement parts.

Connect With Us?

We have a proven track record of designing testing equipment and tests. By sharing our highly developed systems and processes with innovators we’re perfectly placed to support WA-based businesses.